About us

At Aeroblades, our mission is to enhance the performance of your competition vehicle by creating functional and authentic turbofan wheel cooling shrouds. We take pride in manufacturing our turbofans using traditional techniques to ensure quality and reliability. We leverage modern technology to design the perfect turbofan for your vehicle while still maintaining our old-school approaches.

Our process begins with a 3D scan of your wheel followed by creating a CAD model of your wheel and our new turbofan. We then use 3D printing to create a prototype to ensure perfect fitment before sending CAD files off for laser cutting and precision bending.

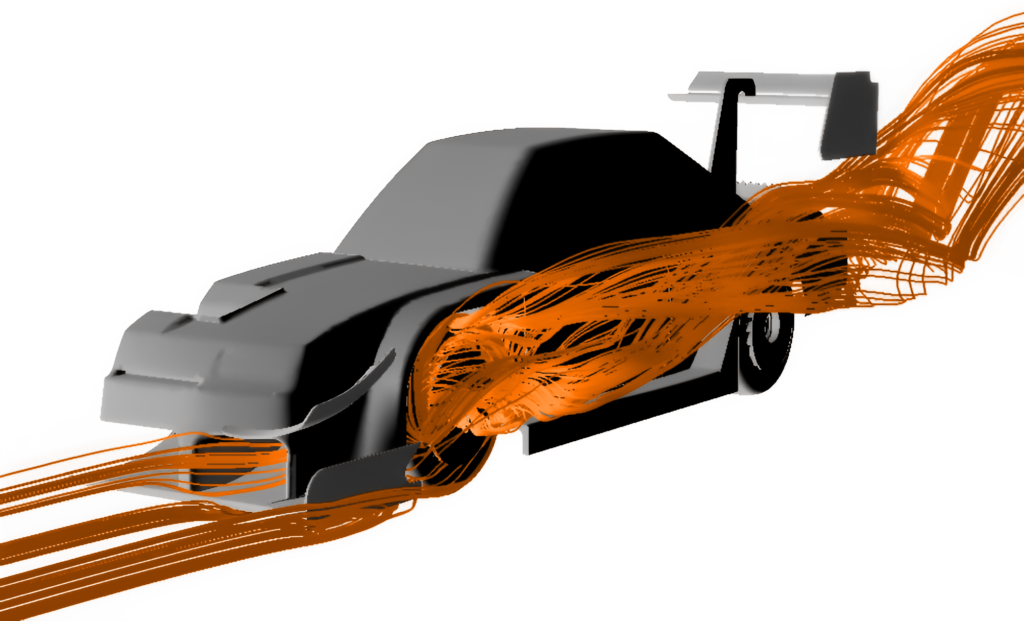

We believe that our product is superior to others, and to prove it, we collaborated with CFD professionals to run simulations to validate our design philosophy. Our tests showed a reduction in drag and increased flow through the wheel for brake cooling as well as an increase in downforce.

Our philosophy is to keep our turbofans simple, lightweight, and functional. Nevertheless, if you want to take your vehicle’s appearance to the next level, we can design your turbofans to include an add-on fascia plate to mimic the look of a wheel. Although this may add some weight, the result is an outstanding appearance when your car is standing still.

Our products are CFD proven

What is CFD?

CFD, or Computational Fluid Dynamics, is a computer-based tool that allows engineers to simulate and analyze how air flows over and around objects. Think of it as a virtual wind tunnel that helps us understand the behavior of air without needing to physically test models in real wind tunnels. This technology uses mathematical equations and algorithms to predict airflow patterns, pressure, and other important factors that affect the performance of objects like aircraft parts.

Benefits of CFD for Turbofan Aero Wheel Covers

Enhanced Design Accuracy: CFD enables engineers to create more precise and efficient designs by providing detailed insights into how air interacts with wheel covers. This means better aerodynamic performance and less trial-and-error during development.

Improved Fuel Efficiency: By optimizing the shape and design of aero wheel covers using CFD, we can reduce drag. This leads to lower fuel consumption, making flights more economical and environmentally friendly.

Reduced Noise: CFD helps identify and minimize turbulent airflow around the wheel covers, which can decrease noise levels. Quieter engines contribute to a more pleasant experience for passengers and communities near airports.

Cost Savings: With CFD, engineers can test multiple designs virtually before building physical prototypes. This reduces the need for expensive and time-consuming physical tests, speeding up the development process and cutting costs.

Enhanced Safety and Reliability: By understanding airflow patterns and potential issues early in the design process, CFD helps ensure that aero wheel covers are not only efficient but also safe and reliable under various operating conditions.